With the development of modern science and technology, industrial borescope is gradually used for inspection of hard-to-reach places such as drains, sewer pipes, heating vents, air ducts, furnaces, motors, pistons, gears, valves, compressors, boilers and condenser tubes.

Thanks to flexible cables and lightweight body, borescope cameras are extremely agile and portable. An industrial borescope inspection camera helps you locate potential problems quickly and easily without the need to dismantle a system or machine, allowing corrective measures to be taken before costly downtime occurs.

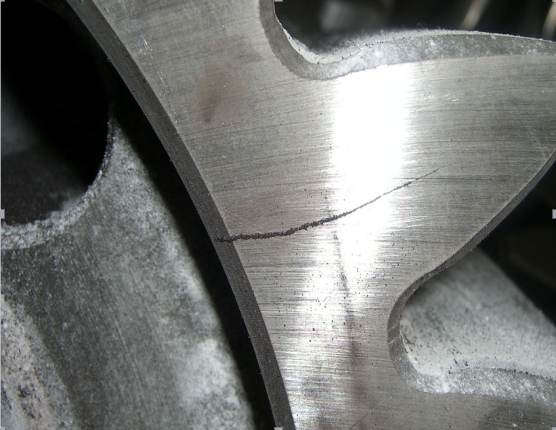

In the maintenance of aeroengines, it is mainly used for inspection of engine turbine blades, compressor blades and combustion chambers, which plays an important role in improving engine utilization and ensuring safety and reliability.

Today’s civil aircraft mostly use high-duct turbofan engines. It is mainly composed by fans, compressors, combustion chambers, turbines and accessory systems. Its comprehensive performance is an important factor to ensure the utilization of civil aircraft and flight safety. In the past few decades, the main method of civil aircraft maintenance was timing (HT) maintenance. It requires equipment or parts to be regularly repaired according to the Instruction manual. This may cause some equipment or components to be disassemble when they are in good condition, just because it is time to inspect. This will result in waste of manpower and material resources inevitably. With the introduction of advanced civil aircraft and engines and the development of science and technology, OC maintenance is rapidly becoming widely used in civil aircraft inspection. It requires periodic inspections of equipments or components against certain physical standards to determine whether they can continue to be used until the next planned inspection or inspection cycle.

An airline found that there was a problem with the combustion chamber when performing borescope inspection on the A310 – 2303 aircraft engine. Due to the correct judgment , avoiding the early hoisting of the engine, which help the company save $1,000,000.00 cost.

Yateks manufacturer specialized in NDT Test & Measurement Equipment for decades. Mainly produce 2.8mm-6mm diameter 360° rotation arbitrarily Turbine endoscope, Auto/Engine endoscopes,industrial borescopes, videoscopes, police military use endoscopes, fiber optic endoscopes, Thermal video endoscopes, Infrared Anti-terrorism endoscopes, UV endoscope with exceptional quality and pretty competitive price. 1 Year Quality Warranty and Lifetime maintenance.